Can be found everywhere...

The newest generation of Alloy plating combined treatment

New RUSPERT®

Substrate zinc-nickel alloy plating realises superior corrosion resistance performance. RUSPERT treatment has evolved into a more environmentally friendly waterborne coating system, whilst retaining its existing strong and minute compound film structure.

Meeting the needs of today

DISGO®

We launched DISGO® — a treatment designed for steel products to which electroplating cannot be applied — entering new fields of zinc flake coating. Thereafter, we added a hot-dip zinc electroplating process to the treatment expanding the lineup.

Alongside our main product RUSPERT®, DISGO® is used in a wide range of industries such as civil engineering and construction, power engineering and transport vehicles.

Innovation in electroplating and painting

RUSPERT®

In the mid 1980s the complex processing of electro-galvanizing and painting, which was revolutionary at the time, was well received by customers who were plagued by acid rain. 30 years on, RUSPERT® is now the world standard in high corrosionresistant metal surface treatments.

High corrosion-resistant thin film

LAFRE®

Developing DISGO®’s zinc-flake coating technology further, LAFRE® exhibits high corrosion resistance in spite of being thin film and is especially well-suited for automotive fastening products. Even under severe corrosion conditions, it can be used without worrying about film thickness or hydrogen embrittlement.

Paint for rust prevention

In addition to corrosion resistance, we can also offer solutions according to your product specifications such as contact corrosion prevention, tightening torque control, and anti-galling for stainless steel products. Choose a colour tone that matches needs, such as decoration or identifications, from our wide list of colour variations. Our newly developed waterborne coating system takes into account environmental conservation, improving working environment conditions and reducing VOC emissions.

Functional coating agent

We have a varied lineup including rust proof sealer and external lubricant and provide solutions tailored to costomers’ needs such as tightening torque control and colouring.

Cold-drying type paint for maintenance

DRALL®

Reflecting our customers’ needs we have developed “DRALL®”: a paint that dries at room-temperature for maintance. This paint utilises our proprietary zin flake dispersion technology and can be used for in a wide variety of situations, such as tool scratches at the time of fastening, welding marks and surface cuts in galvanised steel sheets.

It is environmentally friendly and non-chrome.

As an electroplating specialist, we strive to make sure the plating chemicals and materials we use help produce user-friendly products for our customers.

Chemicals

We supply all of the necessary chemicals related to zinc/zinc-nickel alloy plating for rust prevention from degreasing to chemical conversion treatment.

Introducing a painting process is smooth as RUSPERT® and DISGO® treatments are designed to be used together.

Materials

We provide metal materials and basic chemicals for zinc/zinc-nickel alloy plating, carefully selecting only the best quality products from our global network.

A non-drainage electroplating system using non-aqueous pre-treatment, with recovery and recycling of water, has been in operation at our plant since 2016.

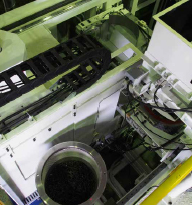

CAELAR® System

A barrel-type electrogalvanising system meeting the needs of today by eliminating water drainage.

There is no risk of toxic substances being discharged, so you can be freed from examination of drainage.

No more waste-water!

Dry Type Pretreatment

By using dry-type pretreatment, the amount of water used for pre-treatment, degreasing and rust removal has been reduced to zero.

Limiting Use of Plating Solution

Reducing the amount of plating solution used minimises rinse water usage.

Recycling Waste Water System

All waste water from the whole process is recycled and reused.

There is no discharge subject to regulation.

Equipment can be customised according to the shape of the workpiece and installation space.

Regardless of the equipment size, we support the whole process from pre-treatment to baking.

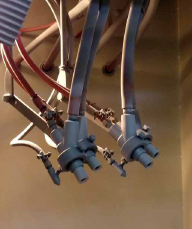

Painting Apparatus

Dip-spin and spray coating methods are available depending on the profile of the products.

With our production technology and know-how we have a wealth of experience in delivering painting equipment, from small-sized equipment for sample making to large-scale automated equipment for mass-production use.

Baking and Drying Furnace

A batch type baking furnace with excellent cost performance and space efficiency, and a continuous type baking furnace with highproduction efficiency are both available.

We have a variety of furnaces with a range of heat sources such as electric and gas, and can propose the optimum type based on customers’ needs.

Pre-treatment Equipment

The process of substrate treatment affects performance.

Equipment for degreasing and blasting are available. Methods and media can be selected depending on your requirements.

Production line optimisation

Effective conveyance of objects is essential during the painting process, therefore our experienced staff can propose the best way to optimise your production line.

Profile

Nihon RUSPERT Co.,Ltd.

President and Representative Director

Toyoaki TSUMURA

Capital

10 million yen

Established

July, 1968

Location

Kishiwada-city, Osaka-prefecture

No. of Associates

100 people

Major

The Senshu Ikeda Bank, Ltd.

Business